| CM/CGV, CMU/CGV Pump Performance | ||||

| Model | GPM | PSI | L/min | bar |

| CM Stand-Alone | 750-1250 | 150 | 3000-4750 | 10.3 |

| CMU Stand-Alone | 1250-2250 | 150 | 4750-8550 | 10.3 |

| CM/CGV | 500 | 700 | 1900 | 48 |

| CMU/CGV | 500 | 700 | 1900 | 48 |

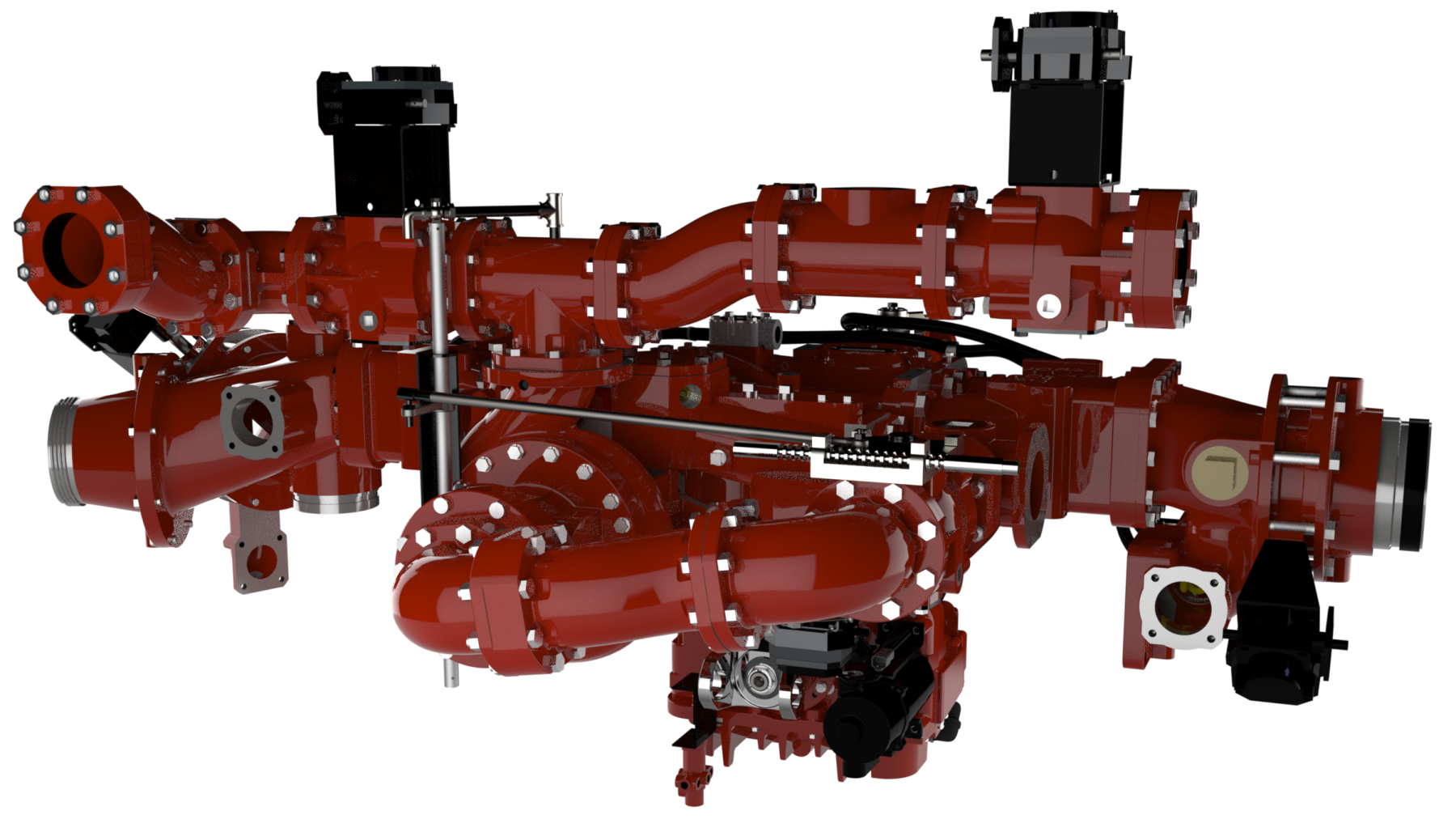

CM/CMU Pump Specifications

Casing:

Two-piece, horizontally-split, high-tensile, close grained gray iron. All passageways are carefully matched to assure the very best hydraulic flow characteristics.

Wear Rings:

Bronze, reverse-flow, labyrinth-type replaceable wear rings increase pump life and keep maintenance costs to a minimum.

Impellers:

Matched bronze impellers, balanced both mechanically and hydraulically for vibration-free operation. Flame-plated impeller hubs (optional on CM, standard on CMU pumps) assure longer life despite the presence of abrasives in the water supply.

Impeller Shaft:

Heat-treated stainless steel is ground at all critical areas, polished under packing. An exclusive two-piece impeller shaft allows separation of the transmission from the pump without disassembling either component. This simplifies repair procedures, resulting in less down time.

Bearings:

Three deep-groove, anti-friction ball bearings, located outside the pumping chamber, give support and proper alignment to the impeller shaft assembly. Bearings are oil or grease lubricated, completely separated from the water being pumped, and protected by seal housings, flinger rings and oil seals.

Shaft Seal:

Seal housings on packed pumps are equipped with braided flexible graphite (BFG) rings held in place by a split bronze gland which is fully removable and adjustable. BFG packing improves heat dissipation, reduces maintenance and minimizes shaft wear. Self-adjusting, spring-loaded mechanical seals are available which eliminate leakage and routine maintenance.

Flinger Rings:

Located on the impeller shaft between seal housings and bearing housings, flinger rings provide added protection and keep water and foreign matter out of the bearings.

Oil Seals:

Standard lip type for lubrication and additional bearing protection from dirt and water.

Transfer Valve:

Ball type bronze valve, in removable bronze housings with large waterways for smooth flow. Manual operation is standard, electric operation is optional. The Waterous transfer valve provides smooth transfer to either PRESSURE or VOLUME without sticking.Pump

CGV Pump Specifications

Casing:

Two-piece, vertically-split, high-tensile, close-grained gray iron.

Impeller:

Bronze impeller specifically designed for the fire service, double-hubbed to eliminate axial thrust, and accurately balanced for vibration-free running. Impellers with flame-plated hubs for extreme wear resistance are optional.

Wear Rings:

Replaceable bronze wear rings to increase pump life and keep maintenance costs at a minimum.

Impeller Shaft:

Stainless steel, heat treated, precisely ground to size, and polished under shaft seal. Supported by oil-lubricated ball bearings.

Bearings:

All bearings are oil or grease lubricated, ball-type, located outside the pump casting to accurately align and support the impeller shaft assembly. Ball bearings are deep-groove type designed to carry both radial and axial thrust.

Shaft Seal:

Double-mechanical seal. The double-mechanical seal chamber provides a water pocket to cool and lubricate the seal surfaces when only the CM pump is being used.

C22 Transmission Specifications

C22 Series

Housings: High-strength aluminum, three-piece, horizontally-split.

Drive Ratios: 2.27, 2.46

Shafts: Drive line shafts made from alloy steel forgings, hardened and ground to size, 2.35 inch 46-tooth involute spline.

Drive and Driven Sprockets

Made of steel. All sprockets are hardened and have ground bores.

Drive Chain

Morse HV® high-strength involute form chain.

Bearings

Deep-groove, anti-friction ball bearings give support and proper alignment to the impeller shaft assembly. Bearings are oil-splash lubricated, completely separated from the water being pumped, and protected by a V-ring and oil seals.

Lubrication System

An internal lubrication system delivers lubricant directly to the drive chain. This unique design eliminates the need for an external lubrication pump and auxiliary cooling.

Shift Mechanism

Constant-mesh, two-position sliding collar that engages all teeth simultaneously. In-cab controlled pneumatic shift . An internal locking mechanism provides a positive lock in PUMP or ROAD position.

Options and Accessories

- Priming System: An electric, oil-free rotary vane primer mounted directly on a Waterous split-shaft pump transmission or separately mounted combined with a Waterous priming valve forms the priming system. A lubrication option allows the use of Prime-Safe lubricant (priming tank is required when the lubrication option is selected).

- Pressure Control System: The Waterous Intake Relief Valve system is designed to act as a safety valve by “dumping” excess pressure from the inlet side of the pump. The Discharge Relief Valve provides sensitive pump control to protect firefighters from sudden pressure surges resulting from changes in discharge flows from the pump.

- Manifold Drain Valve: Drains all points of the pump simultaneously with the operation of a single control.

- H-Manifold Discharge Fitting: Allows for efficient and easy installation of a Waterous pump and significantly improves manufacturing process throughput. Flexible design enables OEM’s to easily adapt to customers’ needs with a wide range of discharge openings. The H-manifold discharge arrangement creates panel dimensions that accommodate remote locking and quarter-turn valves.

- Corrosion Protection: Replaceable magnesium element that is installed directly on the pump intake piping and into the pump waterway. These anodes sacrifice the magnesium element to galvanic corrosion.

- Discharge Valves: Your choice of the trusted Waterous 1⁄4 turn 2.5 inch and 3.5 inch rack and sector push-pull, worm gear and electric discharge valves. All come standard with chrome-plated brass ball and hydraulically balanced seal assembly.

- Overheat Protection Manager: The OPM consists of an illuminated warning light on the operator’s panel whenever the pump approaches an overheat condition. Optional audible alarm is available.

- Foam Manager: Consisting of a 500 or 1000 GPM foam manifold and foam proportioner.

- Power Shift: Pneumatic shift allows operator to shift from ROAD to PUMP position by actuating a valve.

- Tank to Pump Valve: A full-flow 3.5-inch diameter ball valve, which is attached directly to the pump.

- Tachometer: Tachometer drive standard and operates at 1/2 input shaft speed.

- Electric Transfer Valve Actuator: An electric transfer valve provides smooth transfer to either PRESSURE or VOLUME.

- 5-Year Limited Warranty with Total Protection Package (TPP-5): The Total Protection Package is a comprehensive warranty that increases your standard warranty to include labor expenses to dismantle, remove and reinstall covered products or parts.

Pump Information

-

Dimensional Drawings

- DPL82847, CM/CGV, CMUCGV DIMENSIONAL DRAWING

- DPL82501, TRANSFER VALVE ACTUATOR

-

Data Sheet

- DS-1000, DATA SHEET

-

Instructions

- SEC. 2110, OPERATION AND MAINTENANCE

- SEC. 2315, TRANSFER VALVE ACTUATOR

- F-3003, INSTALLATION INSTRUCTIONS

-

Service Parts Lists

- SPL83932, CM/CGV IMPELLER ASSEMBLY

- SPL81344, CM/CGV HIGH PRESSURE BODY ASSEMBLY

- SPL83828, CM / CMU BODY ASSEMBLY

- SPL82910, TRANSFER VALVE ACTUATOR

-

Spec Sheets

- F-2486, CM/CGV, CMU/CGV

- F-1155, TRANSFER VALVE ACTUATOR

-

Performance Sheets

- F-2886, CM/CGV, CMU CGV Performance Sheet

Transmission Information

-

Dimensional Drawings

- DPL82994, C20 DIMENSIONALS

- DPL82086, PUMP SHIFT

-

Data Sheet

- DS-2006, C20 DATA SHEET

-

Instructions

- SEC. 2413, OPERATION AND MAINTENANCE

- SEC. 4315, OVERHAUL

- SEC. 3030, PUMP SHIFT INSTALLATION

- SEC. 3030.1 PNEUMATIC PUMP SHIFT INSTALLATION

-

Service Parts Lists

- SPL83747, C22 TRANSMISSION FOR CM/CMU MODELS

- SPL82990, PUMP SHIFT

-

Miscellaneous Items

- F-2686, DRIVELINE TORQUE RATING

- F-2587, TRANSMISSION SHIFTING INSTRUCTIONS BROCHURE

Pump Information

When you purchase Waterous equipment, not only do you get quality products, you get quality service. Our expert service technicians are the best in the business and they are always happy to answer any service questions you might have. The numbers for our service and training specialists are listed below for your convenience. If you have a general service question please call our main number and our staff will kindly direct you to the appropriate department.